To choose the right cordless tool for cutting and shaping plywood, consider the tool’s power, blade type, and ergonomic features. A proper selection ensures efficient and precise cuts, making your woodworking projects easier and more enjoyable.

Cordless tools with high power ratings are ideal for cutting thick plywood, while those with adjustable blades accommodate various shaping needs. Additionally, opt for tools with comfortable grips, lightweight designs, and efficient dust extraction systems for better control and reduced fatigue during extended use.

By carefully evaluating these factors, you can find the perfect cordless tool for your plywood cutting and shaping needs.

Why You Need The Right Tools

Choosing the right cordless tool for cutting and shaping plywood is essential to achieve the best results in your woodworking projects. Cordless tools offer several advantages over corded tools, making them an ideal choice for this task.

Firstly, cordless tools provide greater mobility and flexibility, allowing you to move freely and work in tight spaces without the constraint of a cord. This makes them highly convenient and versatile for cutting and shaping plywood.

Furthermore, cordless tools are powered by rechargeable batteries, which means you don’t have to rely on electrical outlets or extension cords. This not only increases portability but also eliminates the risk of tripping hazards and tangling cords.

The right cordless tools can also enhance your efficiency and productivity. With advancements in technology, cordless tools now offer high power and performance, comparable to their corded counterparts. This ensures precise cuts and smooth shaping, resulting in professional-looking outcomes.

So, whether you are a professional woodworker or a DIY enthusiast, investing in the right cordless tools for cutting and shaping plywood is a wise decision. Not only will they make your job easier and more efficient, but they will also provide the freedom and convenience needed to tackle any woodworking project.

Essential Cordless Tools For Plywood Cutting And Shaping

Essential Cordless Tools for Plywood Cutting and Shaping

When choosing cordless tools for cutting and shaping plywood, it’s important to consider their functionality and versatility. The following tools are essential for different types of cuts and tasks:

| Circular saw: | The go-to tool for straight cuts, making it ideal for ripping plywood sheets to size. |

| Jigsaw: | Perfect for curved and intricate cuts, allowing you to achieve intricate designs and smooth contours on the plywood. |

| Oscillating multi-tool: | Versatile and adaptable, this tool is great for various cutting and shaping tasks, including plunge cutting, sanding, and scraping. |

| Reciprocating saw: | Ideal for rough cuts and demolition work, this powerful tool can quickly cut through thick plywood or remove unwanted sections. |

| Router: | For adding decorative edges and shaping plywood, a router is a must-have tool. It allows you to create decorative profiles, chamfers, and grooves. |

To select the right cordless tools for your specific needs, consider factors such as power, battery life, blade compatibility, ergonomics, and brand reputation. Evaluate the type of cuts and shaping tasks you frequently perform on plywood and choose the tools that offer the necessary features and capabilities. Remember to prioritize quality and durability for long-term usability.

Mastering Plywood Cutting Techniques

Understanding plywood types and their properties: Before choosing a cordless tool for cutting and shaping plywood, it is important to familiarize yourself with the different types of plywood and their specific properties. This will help you determine the appropriate tool for the job.

Proper measuring and marking for accurate cuts: Accurate measuring and marking are crucial for precise cuts. Use a measuring tape or a combination square to measure and mark the dimensions on the plywood. This will ensure that your cuts are straight and in the right places.

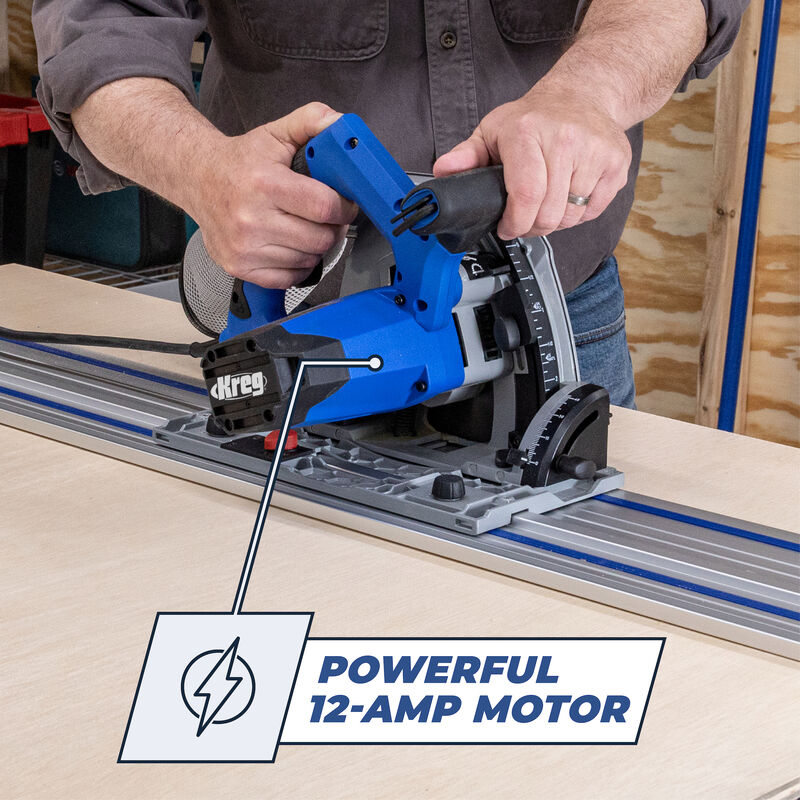

Techniques for cutting straight lines with a circular saw: When cutting straight lines with a circular saw, it is important to use a guide or a straight edge to keep the saw in line. This will help you achieve clean and accurate cuts.

Tips for making curved cuts with a jigsaw: To make curved cuts in plywood, a jigsaw is the ideal tool. Start by drilling a hole in the plywood with a large enough diameter to fit the jigsaw blade. Then, carefully follow your marked line while cutting the plywood.

Utilizing the oscillating multi-tool for precise shaping: An oscillating multi-tool can be used for precise shaping of plywood. Attach the appropriate blade for the desired shape and carefully guide the tool along the marked line to shape the plywood as desired.

Making plunge cuts with a reciprocating saw: A reciprocating saw is useful for making plunge cuts in plywood. Start by drilling a pilot hole at the desired starting point, then carefully guide the saw along the marked line while making the cut.

Creating decorative edges and profiles with a router: If you want to add decorative edges or profiles to your plywood, a router is the perfect tool. Choose the appropriate router bit and carefully guide the router along the edge of the plywood to create the desired design.

Safety Precautions And Best Practices

The safety precautions and best practices for using cordless tools for cutting and shaping plywood are crucial to ensure a safe and effective working environment. One important aspect is wearing appropriate safety gear, including safety glasses, gloves, and ear protection. This protects against potential injuries from flying debris and loud noises associated with cutting plywood.

Proper handling and grip techniques are also essential when using cordless tools. Maintaining a firm grip on the tool and keeping hands away from the cutting area reduces the risk of accidents and ensures precise control over the tool.

To avoid kickbacks and splintering while cutting plywood, it is important to use the correct blade and select the appropriate cutting speed on the tool. This helps to minimize the chances of the tool getting caught or the plywood splintering during the cutting process.

Securing the workpiece properly before cutting is essential in preventing accidents. Clamping or using appropriate supports ensures that the plywood does not move or shift during the cutting or shaping process, reducing the risk of injury or damage.

Lastly, proper maintenance and storage of cordless tools are important for their longevity and performance. Regularly cleaning the tools, checking for any damaged or worn parts, and storing them in a dry and secure location helps to extend their lifespan and ensures they are ready for use when needed.

Pro Tips For Efficient Plywood Cutting And Shaping

Planning your cuts and optimizing material usage is crucial for efficient plywood cutting and shaping. Make sure to measure and mark your cuts accurately before you start. Utilize jigs and templates to ensure consistent and repeatable cuts, saving time and effort in the process.

When choosing the right blade or bit for the desired result, consider factors such as the type of cut you want to make, the material of the plywood, and the thickness. A fine-toothed blade is suitable for clean and smooth cuts, while a special blade for plywood can prevent chipping. Similarly, a router bit specifically designed for plywood shaping can help achieve the desired contours and edges.

Maximizing battery life is essential for prolonged working sessions. Ensure your cordless tool is equipped with a high-performance battery and consider using a lower power mode when necessary. Charging spare batteries in advance can ensure uninterrupted work, avoiding unnecessary interruptions.

Troubleshooting common issues and challenges during cutting and shaping is also important. If you experience tear-out or splintering, try using masking tape along the cut line to minimize damage. Additionally, ensure that the blade or bit is sharp and in good condition, as dull tools can cause more issues. Proper maintenance of your cordless tool will also contribute to its longevity and performance.

Credit: chascrazycreations.com

Projects And Ideas For Plywood Cutting And Shaping

Choosing the right cordless tool for cutting and shaping plywood is essential for any woodworking project. With the variety of projects and ideas available for plywood cutting and shaping, it’s important to have the right tool for the job. Whether you’re building a custom bookshelf with adjustable shelves, creating a plywood tabletop with an integrated cable management system, constructing a floating shelf with hidden mounting brackets, designing and building a plywood storage rack for your workshop, or customizing a plywood headboard with intricate patterns and shapes, having the right cordless tool will make all the difference. Consider factors such as the type of cutting or shaping you will be doing, the power and battery life of the tool, and any additional features that may be useful for your specific project. By choosing the right cordless tool, you can ensure a smooth and successful plywood cutting and shaping experience.

Frequently Asked Questions For How To Choose The Right Cordless Tool For Cutting And Shaping Plywood?

How Do I Choose The Right Cordless Tool For Cutting And Shaping Plywood?

Select a cordless tool with sufficient power and a sharp blade. Consider the tool’s weight, ergonomics, and battery life. Look for features like adjustable speed, dust extraction, and easy blade changes. Check customer reviews to ensure durability and reliability for tackling plywood projects effectively.

What Type Of Cordless Tools Are Best For Cutting And Shaping Plywood?

Circular saws and jigsaws are ideal for cutting plywood, while routers excel at shaping edges and creating intricate designs. Cordless reciprocating saws are great for rough cuts, while oscillating multi-tools offer versatility for various cutting and shaping tasks. Choose based on the specific needs of your plywood projects.

Are There Cordless Tools Specifically Designed For Plywood Cutting And Shaping?

Yes, some cordless tools are designed with plywood in mind. Look for models that offer specialized features such as laser guides or adjustable baseplates for precise cuts. These tools may offer better control and accuracy, making cutting and shaping plywood easier and more efficient.

How Important Is Battery Life When Choosing Cordless Tools For Plywood Work?

Battery life is crucial for cordless tools, especially when working with plywood. Opt for tools with longer battery runtime or consider purchasing extra batteries to avoid interruptions in your projects. Ensure the battery is compatible with other tools you own, allowing for easy interchangeability and extended usage.

Conclusion

To sum up, choosing the right cordless tool for cutting and shaping plywood doesn’t have to be overwhelming. By considering factors like power, blade size, versatility, and ergonomics, you can find a tool that meets your specific needs and preferences.

Remember to prioritize safety by wearing appropriate protective gear and operating the tool responsibly. With the right cordless tool in your hands, you’ll be well-equipped to tackle any plywood project with ease.